Hi, I'm Abhi, an Aerospace Engineer driven by an insatiable curiosity and a passion for turning ambitious ideas into reality. From designing and manufacturing jet engines and pioneering in autonomous robotics to building software that bridges the gap between the digital and physical worlds, I am fueled by a love for exploration and self-learning. With every project, I strive to push boundaries and inspire innovation in aerospace and beyond.

Hi, I'm Abhi—an Aerospace Engineer driven by an insatiable curiosity and a passion for turning ambitious ideas into reality. From designing and manufacturing jet engines and pioneering in autonomous robotics to building software that bridges the gap between the digital and physical worlds, I am fueled by a love for exploration and self-learning. With every project, I strive to push boundaries and inspire innovation in aerospace and beyond.

Hi, I'm Abhi, an Aerospace Engineer driven by an insatiable curiosity and a passion for turning ambitious ideas into reality. From designing and manufacturing jet engines and pioneering in autonomous robotics to building software that bridges the gap between the digital and physical worlds, I am fueled by a love for exploration and self-learning. With every project, I strive to push boundaries and inspire innovation in aerospace and beyond.

Hi, I'm Abhi—an Aerospace Engineer driven by an insatiable curiosity and a passion for turning ambitious ideas into reality. From designing and manufacturing jet engines and pioneering in autonomous robotics to building software that bridges the gap between the digital and physical worlds, I am fueled by a love for exploration and self-learning. With every project, I strive to push boundaries and inspire innovation in aerospace and beyond.

My Journey

Watching scientists juggle colorful chemicals fascinated me as a child, but Mechanix, a toy of bolts and beams, shifted my focus to engineering. Building helicopters and battle-bots sparked my creativity. And the launch of the STS-135 (the last Space Shuttle) finally ignited my passion for flight. This love for aerospace continued strong through my childhood, even when faced with missions that didn't quite seem to go nominally...

Abhi's Space Program didn't quite take off...

Aerospace Engineering

2023 - 2027Iowa State University has been the launchpad for my aerospace journey, where I'm tackling everything from advanced thermodynamics to structural design. With a GPA of 3.83, I am immersed in projects like designing combustion chambers and modeling avionics.

Cyber Physical Systems

2025 - 2027As a natural extension of my aerospace passion, I'm pursuing a minor in Cyber-Physical Systems to master the art of integrating software with hardware. I am pursuing cutting-edge technologies like autonomous navigation, simulation design, and embedded systems.

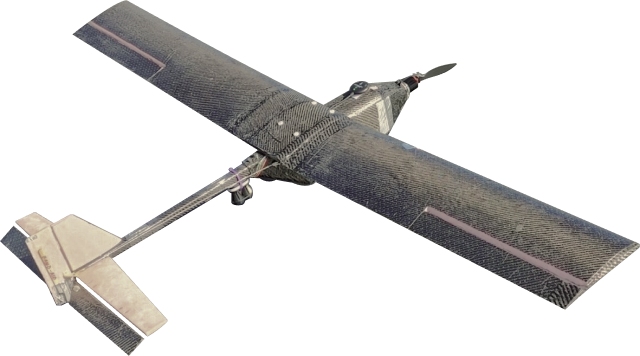

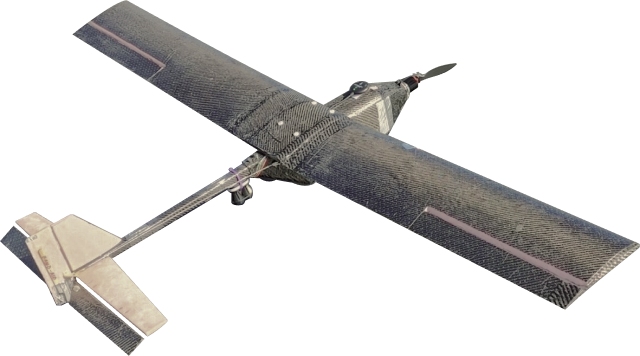

OpenUAS

Aug 2025 - PresentGitFPGAAnsysSolidWorksC++Python

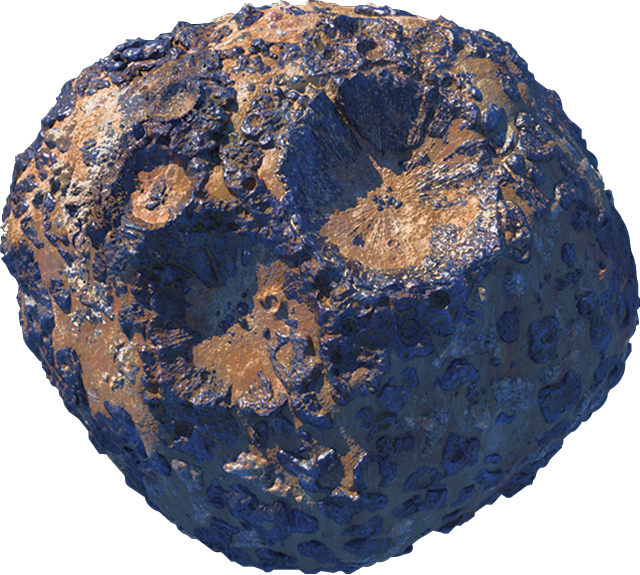

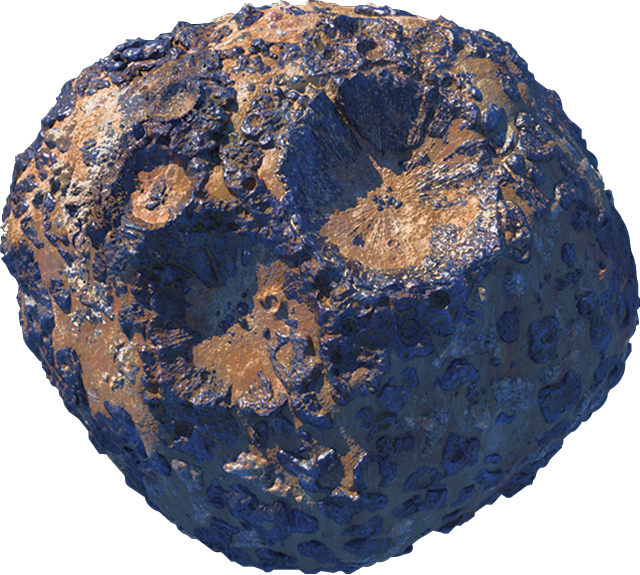

NASA Psyche Intern

Sep 2025 - Present

Zephron

Sep 2025 - PresentGitMATEK FCOnShapeSolidWorks3D Printing

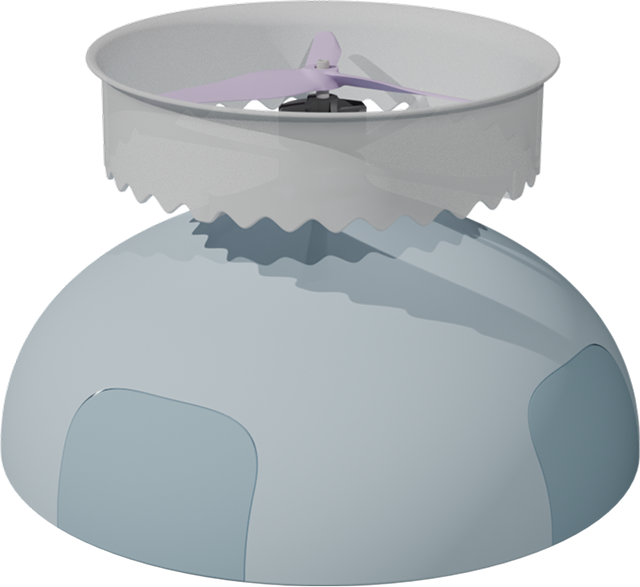

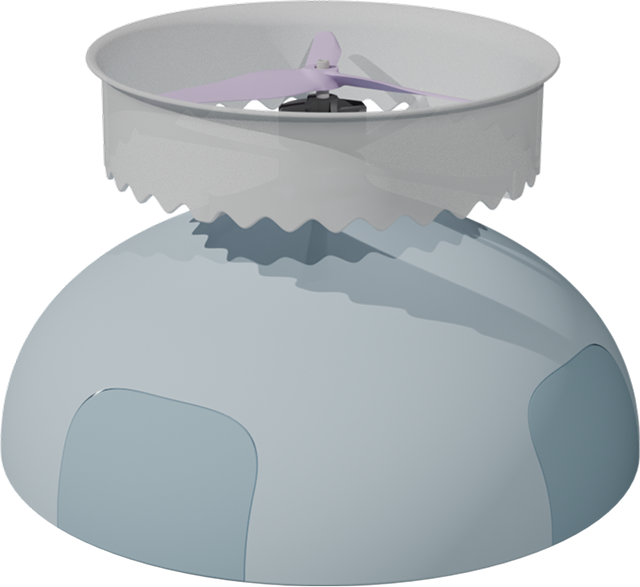

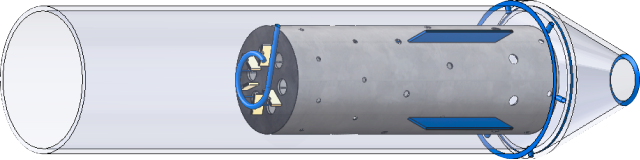

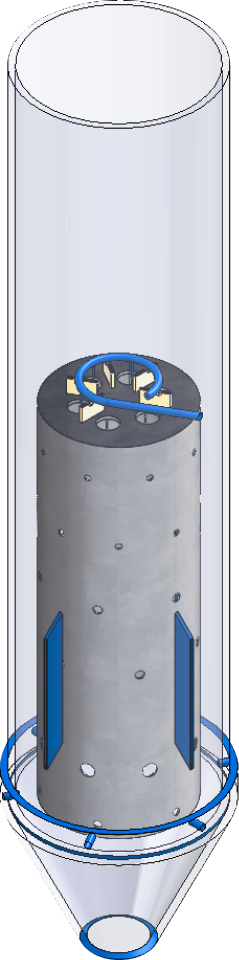

J.E.T.

Aug 2024 - PresentAdvanced ThermodynamicsSolidWorksComputer Fluid DynamicsPython

- Primary Holes: Sixteen holes consume about 20% of the airflow, sustaining the flame.

- Intermediate Holes: Twelve holes use 30% of the airflow to combust any remaining fuel and slightly cool the products.

- Dilution Holes: Eight holes consume the remaining airflow, cooling the products further to protect downstream aluminum components.

BlitzKit

Apr 2022 - PresentLarge Public ProjectGitHubTypeScriptC#WebGL

Nerdy Birds

Aug 2019 - May 2023Team LeadComputer VisionInertial NavigationJava

And I dabble with a bit of painting...

Unnamed Doublet2025

Bob Ross-style 30 minute paintingsCarina Nebula2023

Faithful recreation of the iconic James Webb image